Technical article

Heat Cycle Characteristics

For automotive applications where high heat cycle characteristics are required, solder cracks may be critical for flat chip resistors especially for large size. Solder crack is a phenomenon that crack is caused in solder when the temperature cycle, the gap of linear expansion coefficient between circuit substrate and chip resistor, is given to the solder junction area and the stress focuses on the area. It will lead to bad solder connection.

When it requires large rated power, large size chip resistor is generally used while the large the product size is, the more frequently the solder cracks are caused. To achieve both high power and the countermeasure to solder cracks, plural resistors of the smaller size and the lower rated power are used but it will require the more number of components and the mounting surface area.

In that case, wide electrode type WK73S, of high rated power and heat cycle or molded type TSL・SL・SLN is recommended.

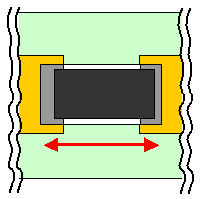

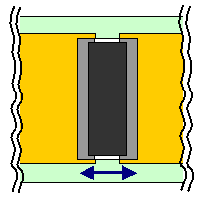

Wide terminal surface area offers excellent heat radiation and achieves rated power. Wide terminal type with reversal height and width against standard type, has short distance between electrodes. and higher heat cycle resistance. The rated power is higher because of the excellent heat radiation and wide electrode surface area.

General-Purpose Type Wide Terminal Type

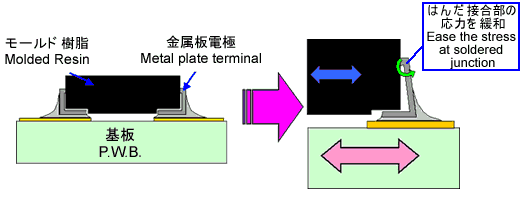

Molded type has terminal construction as below which enables to ease the stress of solder junction under heat cycle.